| 08-26-2020, 09:36 AM | #157 | ||

|

Captain

518

Rep 744

Posts |

I am, shoot me a PM.

Quote:

My PLA one melted. Im printing them in ABS and they seem to be holding up. Kankles can show you a melted PLA one. Quote:

What is the outlet DIA of your new ones? I am adding temp strips tomorrow and will run scoops and blocked scoops to compare results  Lets hope its dry so we can stomp the brakes hard. Lets hope its dry so we can stomp the brakes hard.

__________________

AX 1.1 --> AX GTI --> NA Roadster 1.8 --> E39 528i --> Xsara VTS --> Volvo 940 LPT --> Focus RS MK3 --> M2C + NA Miata 1.8

|

||

| 08-27-2020, 03:52 PM | #159 |

|

Captain

518

Rep 744

Posts |

Got to try my scoop setup today with some temp strips!

Setup: M2 Comp stock DCT DSC OFF Motul RBF 600 Fluid (couple track days old) Pagid RSL 29 brake pads Front: 1 track day old Rear: Multiple track days old, now at minimum thickness) Brake Cooling Setup Front: 55parts carbon backing plate and own 3D printed scoops Rear: Stock backing plates and own 3D printed arm scoops First the subjective, I started the day with the scoops fitted and ran them most of the time. The session was cut up into 1-1.5h long chunks of which most were driven with the odd interruption to check tire pressures and get gas. Longest stint was 30-40min. I had 0 brake fade during the day and improved my best time at Assen by a second (even though there was a ton of traffic!). For comparison my friends M4 with the same pads (but more power and grip) faded his OEM brakes. I only ran the last 15-20min without the scoops (took longer to remove than I planned). The brakes had cooled a lot while removing them. I pushed hard during the last stint and only got a hint of fade towards the end. I think 10-15min more and the pedal would have been too long. Results Top pic is 1h in with pauses for tire temp checks etc Middle pic is after most of the sessions were done Bottom pic is 15-20 min without a scoop While I didn't get more pics, I did keep an eye on the temp stickers while pitting and with the scoops they simply stopped changing at some point. Conclusion More testing needs to be done! I didn't get enough time with the stock cooling to fade them. However trackparts.ch did a similar test and got stock temp values of 210C for the front and 182C for the rear (ME 22 pads, N55 F87 so no front bumper cooling). Which is much higher than what I achieved with the scoops. https://trackparts.ch/Bremsen-optimieren-BMW-M2-M3-M4 However its clear to see that without the scoops the rear brakes already started getting hotter and that the right front caliper also got a bit hotter (Assen runs clockwise). The front left seemed unchanged. The fronts may have changed less than the rear as they had more pad material slowing the heat transfer. More time on track without the scoops would have likely resulted in a larger temperature delta. The front scoops are perfect for me and provided sufficient cooling. My friend with an M3 also had them fitted, his car and also experienced no fade, and they even survived a small geological expedition. The rear scoops need some slight tweaking as I forgot suspension compression is a thing and lost a bit of them during the day.... Aerowise they seem perfect though.

__________________

AX 1.1 --> AX GTI --> NA Roadster 1.8 --> E39 528i --> Xsara VTS --> Volvo 940 LPT --> Focus RS MK3 --> M2C + NA Miata 1.8

Last edited by Megator; 08-28-2020 at 12:29 AM.. |

|

Appreciate

8

|

| 09-05-2020, 04:19 AM | #160 |

|

eric

25

Rep 28

Posts |

[IMG][/IMG]

Here is my setup with Burkhart engineering backing plates and minimania scoops |

|

Appreciate

1

FrankMstein1015.00 |

| 01-03-2021, 12:47 AM | #164 |

|

New Member

14

Rep 28

Posts |

|

|

Appreciate

0

|

| 01-04-2021, 03:27 AM | #165 |

|

Captain

518

Rep 744

Posts |

Not sure what your after but mine is similar to magnusT's and the rest of the under arm scoop ones.

See https://f87.bimmerpost.com/forums/sh...&postcount=150 On an M2C you could grab air from the brake cooling ducts placed between the radiator cores but this would require a lot of modification as on full lock there is less than an inch between the tire and the inner fender (less if you go with a wider wheel) The M2CS racing does this, see the 2nd pic in this post. The middle duct to the brakes comes from the front. The blanked off rectangle to the outside of the funnel of the center hose is where the OEM brake cooling scoop outlet is. https://f87.bimmerpost.com/forums/sh...4&postcount=52 I didnt persue this as I thought the under arm scoop + front scoops would be beter than a directed front scoop only. I have no issues on track with the brakes now and am slightly regretting buying some APs. Maybe when its dry again I wont say that though.

__________________

AX 1.1 --> AX GTI --> NA Roadster 1.8 --> E39 528i --> Xsara VTS --> Volvo 940 LPT --> Focus RS MK3 --> M2C + NA Miata 1.8

|

|

Appreciate

0

|

| 01-18-2021, 09:40 AM | #167 |

|

BimmerPost Supporting Vendor

1025

Rep 842

Posts  |

Gents,

Below is a link to an article we (Essex Parts Services) recently released regarding brake ducts on production road cars. We compiled this information after looking at brake duct solutions across a wide range of popular track day and club racing vehicles. We hope you find it useful! Do I need brake ducts on my track car? |

| 01-18-2021, 09:45 AM | #168 | |

|

Lieutenant

437

Rep 485

Posts |

Quote:

|

|

|

Appreciate

1

RedSectorA37.50 |

| 01-19-2021, 11:13 AM | #169 | |

|

Brigadier General

2811

Rep 3,695

Posts |

Quote:

No fade and even wear even on the toughest braking tracks, works all year round for the street, and no time, effort, or fuss designing, paying for, installing, or maintaining a duct setup for a street caróbetter to use that cash & effort for some APís, and save messing with ducts for the race car. And for anyone using expensive carbon backing plates in your duct setup, Iíve seen those catch on fire at the track. Bad idea! |

|

|

Appreciate

2

DrKevM52269.00 jritt@essex1024.50 |

| 01-19-2021, 11:17 AM | #170 | |

|

Brigadier General

2811

Rep 3,695

Posts |

Quote:

Plus, if you’re a serious braker the calipers will still get hot enough to discolor the paint even with ducting. The best advice is to pull them off and set them aside for later when you sell the car, and to buy, use, resell a set of AP’s for track use in the meantime. |

|

|

Appreciate

0

|

| 01-19-2021, 12:40 PM | #171 | |

|

BimmerPost Supporting Vendor

1025

Rep 842

Posts  |

Quote:

The start of that chain is the pad/disc interface. If your discs don't have enough thermal capacity or aren't efficient enough at flowing cooling air they will: Cause your pads to overheat and fade or crumble Crack Deform/cone (assuming they can't float) If your pads do not have a high enough max operating temperature to handle what's being asked of them (street pads being used on the track for example), they will potentially: Fade Burn up rapidly Melt onto your disc face and cause vibrations Solving the above two issues is at the root of many customer problems we see. Further downstream of the pad/disc interface is when other factors come into play. If you have a disc that's running incredibly hot however, that is the root of the problem. That's why some people try to solve the issue by installing ducts. As discussed in our article, many times that doesn't work out so well. If the disc you're running can't leverage and flow the cooling air you're blowing into/onto it, you're not making any progress towards your goals. All you're doing is complicating your setup and wasting your time. OEM style discs tend to be incredibly inefficient. They have narrow air gaps, and the vanes tend more towards creating a stable disc face (pillar vane) rather than promoting airflow. They also can't float when they get to track temps, or if they can float, they many times don't have enough float. We see that with dual-cast OEM discs. An overheating disc leads to ---> overheated pads---> overheated caliper pistons---> overheated brake fluid--->overheated caliper body People often try to solve their brake issues by starting at the wrong end of the chain. I've seen people put a nice caliper on a sh@tty disc, expecting some type of revelation in braking. All they get is a hot disc with a nicer overheated caliper sitting on it. Running an aftermarket caliper or a take-off from a different vehicle on an OEM style disc is pointless unless all you want your brakes to do is look good. Another approach people take is to install good racing pads on an OEM disc. If they disc is running hot enough, it doesn't matter what pads you have in the caliper. You will overheat them, they will burn up quickly, they will create uneven pad deposits, and have other types of problems. Some people install stainless steel pistons in an OEM caliper and expect their brake problems to be solved. If the discs and pads are running too hot, you're not really solving the root of the problem. All you are doing is delaying the onset of heat soak into your fluid. You need to address the root of the issue. A properly designed and implemented track brake system addresses all aspects of heat rejection. It starts with a disc that has enough mass and airflow to absorb and shed the heat being generated. On that disc must sit a pad capable of handling the max temperatures being generated on the disc face. At the same time those pads need to generate adequate friction at those temps, and it must not wear out quickly at those temps. The caliper then forms another layer of heat rejection via stainless pistons, ventilated pistons, etc. Those features help keep brake fluid temperatures down, but the fluid must have a high enough dry boiling point to handle the sustained temps it's seeing. All the components must complement each other. What we've seen, as others have noted, is that a properly designed system doesn't need ducts in most cases. That's not all cases. We do run into the occasional customer on the lunatic fringe pushing insane power, running Hoosiers, massive Aero, and running hour-long+ track sessions or races. In those cases, they could potentially exceed the heat capacity of one of our systems. That's pretty darn rare in our experience though, and I don't know of any M2 out there for which that has been the case. When we design our Competition Kits for a specific chassis, we are building in some overhead for modifications. We know our customers aren't going to be running a bone stock car! We explain our design process in this video, and I think it gives some good insights into how all the features of the various brake components work together to solve heat issues. Last edited by jritt@essex; 01-19-2021 at 12:56 PM.. |

|

| 05-31-2021, 01:24 PM | #172 | |

|

Captain

433

Rep 753

Posts |

Quote:

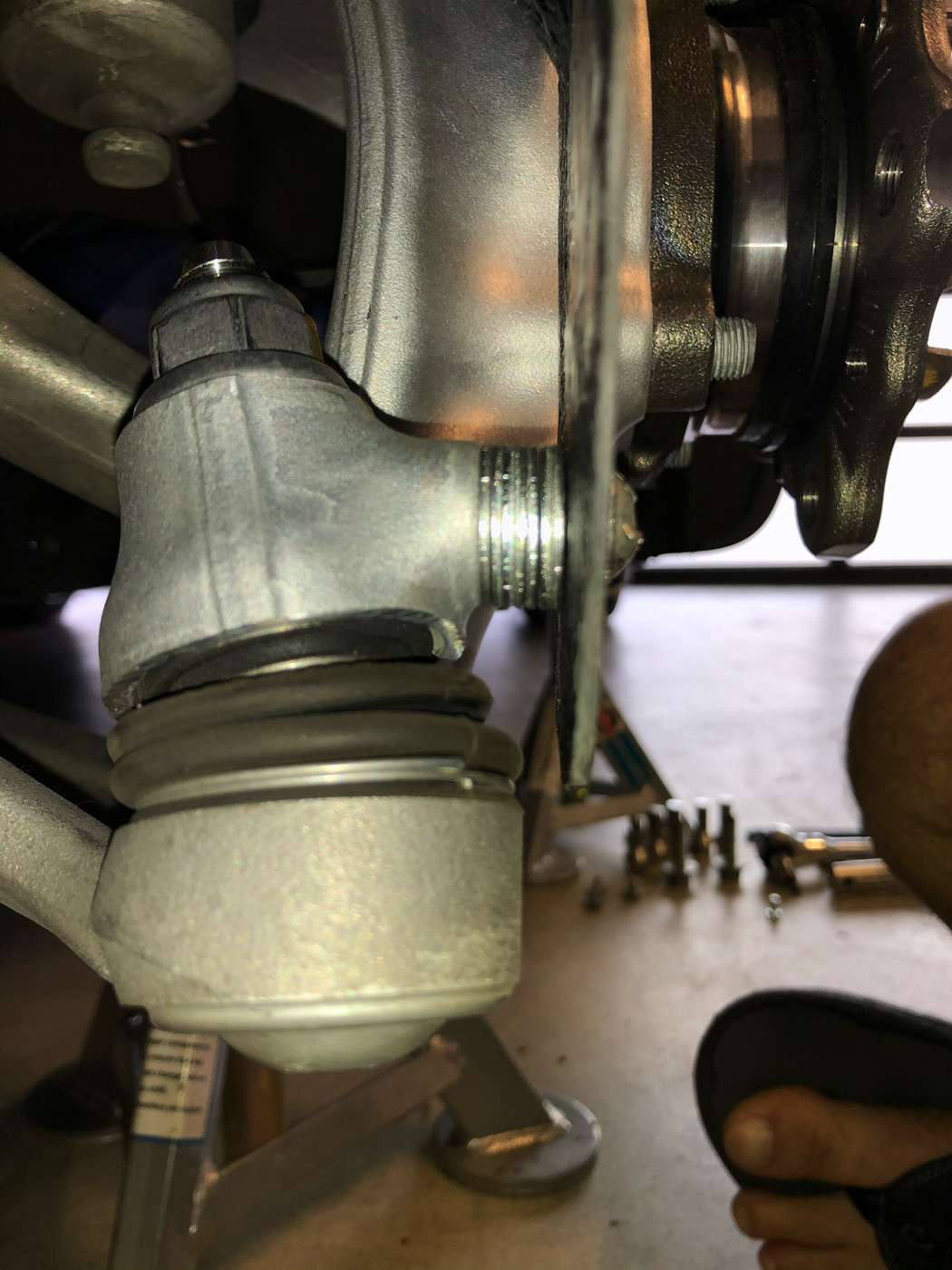

I also had to use a stack of spacers and a longer bolt to have the shield clear the lower ball joint.  Got them both installed, and used blue loctite on the bolts so they don't vibrate loose.  I have a track event this weekend, so planning to simply use a hose to direct air into the plate and will figure out a scoop later. |

|

|

Appreciate

0

|

| 06-01-2021, 02:08 AM | #173 | |

|

Major General

7240

Rep 7,419

Posts |

Quote:

https://www.essexparts.com/news-blog...n-my-track-car edit - i noticed ap racing has already linked it above lol.

__________________

Click on the link below to see a compiled list of every review I have ever written:

https://f87.bimmerpost.com/forums/sh...2#post30368242 Last edited by F87source; 06-01-2021 at 02:14 AM.. |

|

|

Appreciate

0

|

| 06-01-2021, 09:34 AM | #174 |

|

Colonel

2269

Rep 2,519

Posts |

I'm the OP who started this thread, and I've watched it steadily grow with so many innovative engineering solutions. I felt compelled to update my situation. The pandemic gave me time to install a number of upgrades to make my car much more track focused. I decided to stop trying to reinvent the wheel, and invested in the AP CP9660 front brake kit. This system is absolutely incredible! I installed them last summer, however I wasn't able to do my first track event until a month ago. The venue was New York Safety Track, which is a very technical track with one very long straight (doubles as a Runway!) but 18 turns. The brake system totally transformed my track experience. Absolutely no fade, and trust me I was trying to test the limits of the system. Brake pad changes are incredibly easy. Perfectly balanced with the stock rear system, and I used Pagid RS29 pads. It is one of the very best upgrades have done to my track toy. If you are a SERIOUS track addict, I highly recommend making the investment and getting the system. It even caused me to takeoff my old custom ducting system that I had engineered for it. Totally unnecessary, and may even hamper the braking efficiency of the system.

__________________

?16 M2 Long Beach Blue/Black, 6MT

'22 X5 4.0 M Sport Black Sapphire/Tartufo ?22 Tesla Model Y Performance Midnight Silver/White |

| 06-01-2021, 12:15 PM | #175 | |

|

Brigadier General

2811

Rep 3,695

Posts |

Quote:

Atho, I did leave my Porsche air deflectors on just to help direct some air into the hats, but no ducting needed. |

|

|

Appreciate

3

|

| 06-01-2021, 03:32 PM | #176 | ||

|

Colonel

2269

Rep 2,519

Posts |

Quote:

__________________

?16 M2 Long Beach Blue/Black, 6MT

'22 X5 4.0 M Sport Black Sapphire/Tartufo ?22 Tesla Model Y Performance Midnight Silver/White |

||

|

Appreciate

1

ZM22810.50 |

Post Reply |

| Bookmarks |

|

|