When BMW unveiled the M2 MotoGP safety vehicle in the first quarter of 2016, dealers had yet to receive a single factory example to their showroom floors. The M2 received the full suite of M Performance modifications from BMW ///M, as well as other interior and exterior custom components that were exclusive to the vehicle. With the unveiling, it was greeted with a large positive response from the community due to its performance with little to no compromise approach. With the image of the car in their minds, enthusiasts that received their M2’s went straight to modifying their vehicles with many of the available M Performance parts that BMW had made available. However, the front lip was one piece that was left out of the parts list.

In light of the positive response towards the front lip from the community, RKP set out to design a lip that improved upon BMW Motorsport’s design. With only a few of the lips made specifically for the MotoGP safety vehicles, RKP’s design of the lip had to be done from the ground up.

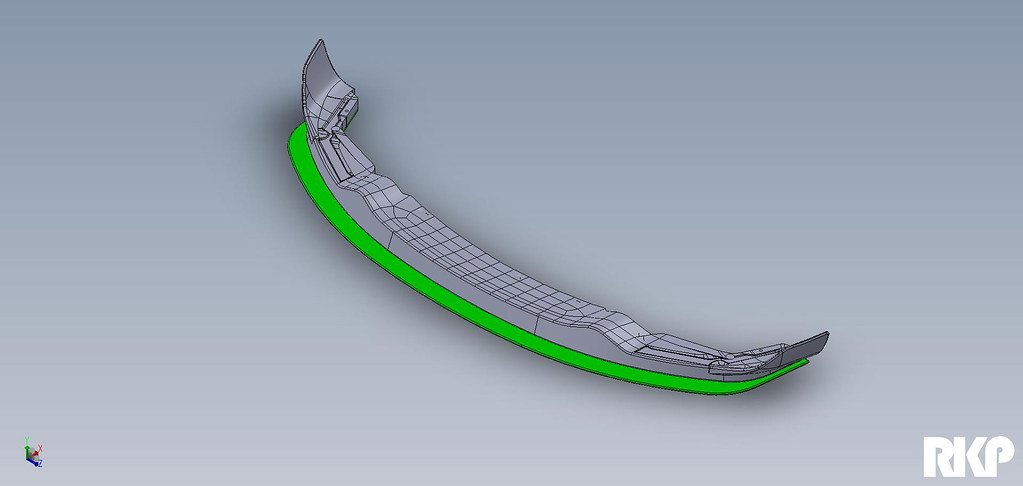

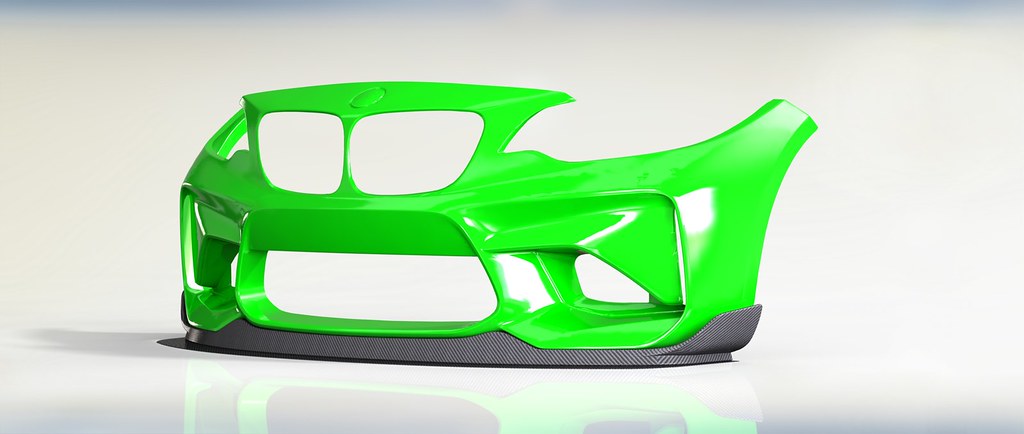

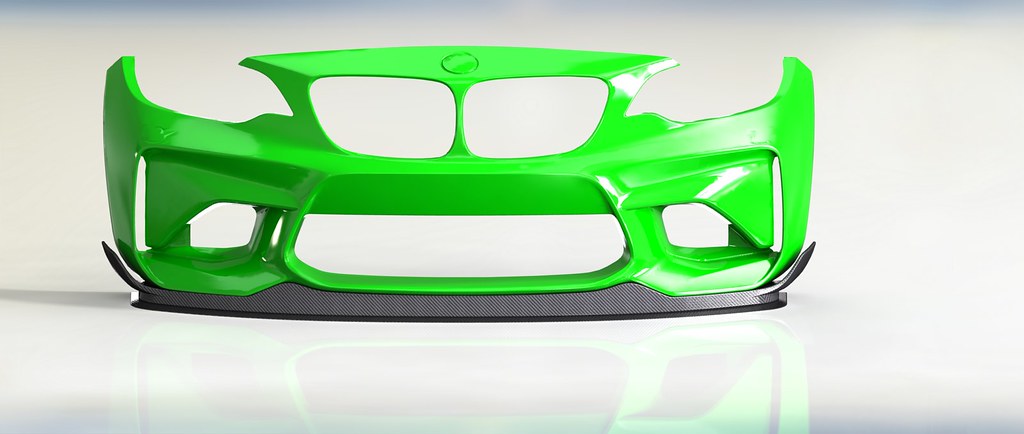

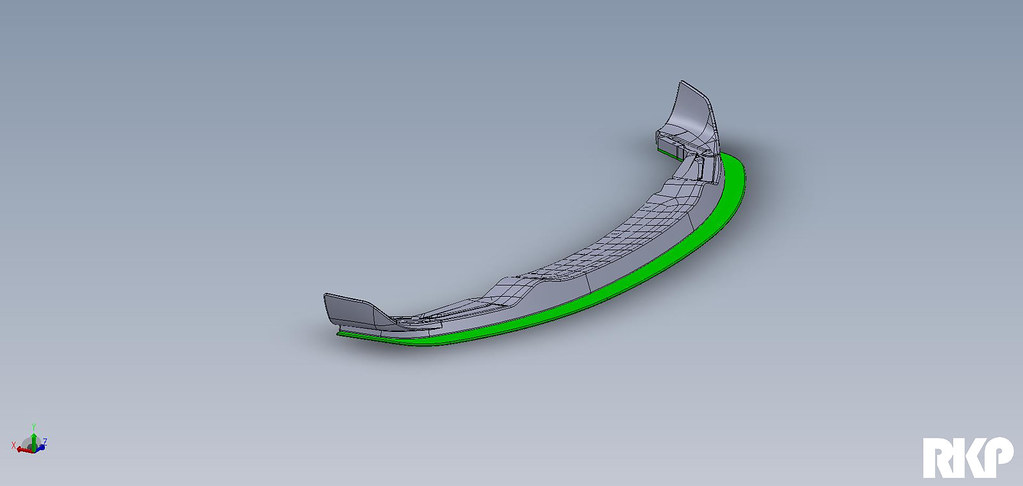

The upper portion of the M2 MotoGP lip was made by BMW Motorsport to contour the lower body line of the front bumper with recessed areas to accommodate the M Performance front bumper winglets. During the design of the RKP version, the winglets were integrated into the profile for a cleaner single piece appearance. In addition to the upper portion of the lip, there was a fixed lower splitter designed similar to the appearance of the original. The initial design for the lip was done in designworks, with all visualizations of it mounted to the bumper handled through keyshot.

Once the design was finalized, prototypes of the upper lip and lower splitter were milled from PVC to the dimensions of the CAD design file.

With the completed prototype, the lip was painted satin black, test fitted and final adjustments and modifications were made to ensure precise fitment to the M2's front bumper.

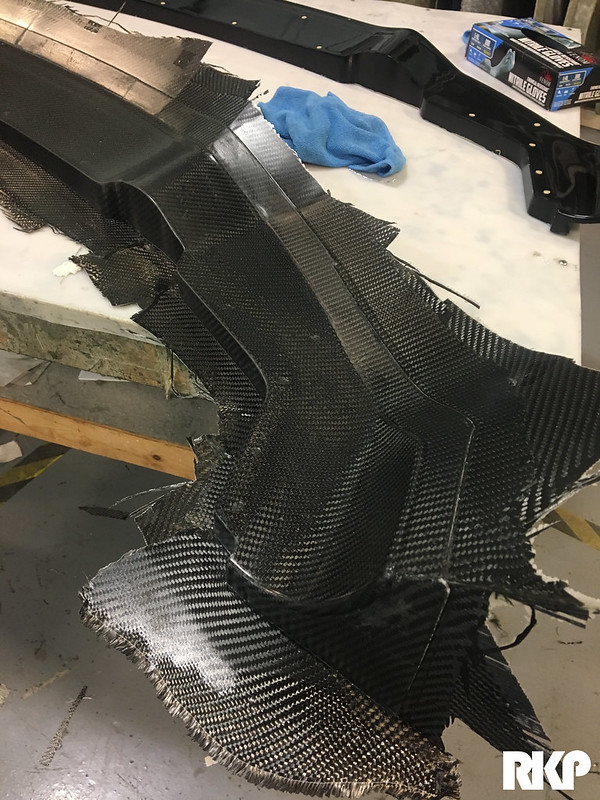

Once the prototype was complete, tooling and production processes were all carried out in house at RKP. The upper lip and lower splitter are constructed using a vacuum infusion process, giving the pieces added strength and durability. These bi-products are a result of an excellent carbon fiber-to-resin ratio, and no voids present in the finished composite due to the vacuum infusion.

The construction of the upper front lip starts off with the carbon fiber being hand laid into the master mold. Hand laying the carbon provides long term durability, a high level of finish, and a complete geometric shape with regards to the mold.

After the carbon is laid into the mold, the lip undergoes the vacuum infusion process where air is pulled out of the carbon fiber, and epoxy goes in. The mold is covered with green peel ply and flow media which make a controlled flow of epoxy possible during vacuum infusion.

Once vacuum infusion is complete, the finished product is removed from the mold.

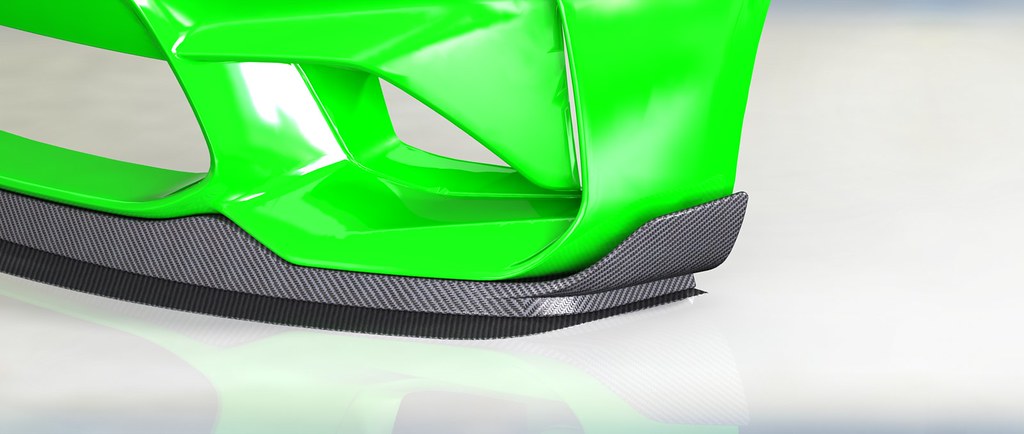

When the two sections of the upper lip are constructed, they are bonded together and laid on a certified flat surface. This allows for inspection to ensure that the underside of the lip is flat, so it can successfully be mated to the lower splitter.

The lower splitter is a clamshell design with a Nomex cell core and integrated aluminum hardpoints. Though Balsa cores are most frequently used in a front splitter application due to being very lightweight, if external damage exposed the core of the splitter, balsa is very moisture absorbant and would cause deformation of the lip over time. Nomex is superior in this regard, as it will not absorb moisture.

The end product is a solid, one piece construction for the upper lip and lower splitter respectively, using only non-commercial, high-grade carbon fiber.With the process being done in the same facility from start to finish, part validation and vehicle fitment procedures can be conducted with ease, assuring quality of the final product.

The IND M2 is now headed to Sema and will be at the BBS Booth #V102